Today, 3D printing technology, using heat-resistant metal alloys, is revolutionizing trial-and-error rocket development.

It’s free, every week, in your inbox.

Thats because rocket engines are incredibly complex.

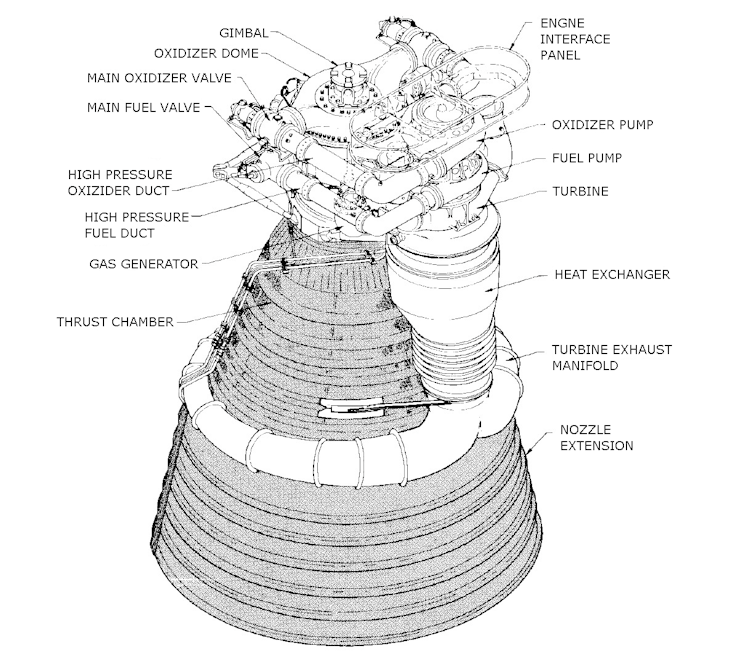

The Saturn Vs F-1 engines that blasted Neil Armstrong towards the Moon in 1969 each had5,600 manufactured parts.

The F-1 rocket engines that launched Apollo 11 towards the Moon were made of thousands of individual parts.

The easiest way to do this is to change manufacturing processes.

That means 3D printing.

Increasingly, engineers are favoring a process calledselective laser sinteringto 3D-print rocket engine parts in an additive process.

The metal binds where its melted, and remains powder where its not.

How engineers 3D-print parts.

Business viable

That matters for private space enterprises.

Building a rocket isnt cheap.

Investors may get flighty as the RUD scrap heap begins to mount.

Virtually all new rocket companies and space startups are adopting 3D metal-printing technology.

In the UK theres,SkyroraandOrbex.

The latter aims to launch a rocket using a 3D-printed engine as early as 2022.